The facilities of the new factory located in the PCI - Parque Canoas de Inovação, were designed with the concept of industrial minimalism, sustainability, and energy conservation. They feature natural light utilization and architectural elements used to prevent direct sunlight radiation into the building interiors, promoting energy savings.

Artificial lighting employs high-power factor LED technology with low total harmonic distortion, controlled by SMART MyHouse Presence Sensors, comprising dozens of different automation networks.

External lighting is controlled by Smart MyHouse photocontroller relays activating high-efficiency LED luminaires. The air conditioning system utilizes VRV inverter technology that uses environmentally friendly gas with higher efficiency. Rainwater supplies toilets, cleaning points, irrigation, and machine cooling from a cistern with a capacity of 60,000 liters.

The internal communication network is based on optical fiber and GPON POL technology, enabling data and electrical energy traffic through the same cable, providing power and connectivity for devices such as wireless access points, IP cameras, IP phones and other equipment compatible with the Power over Ethernet standard, ensuring high performance, robustness and reliability. The industrial plant was designed with sequential assembly lines and advanced automation, resulting in high production volumes and high competitiveness. The well-being of employees was a priority issue in infrastructure planning, with the Lounge, a space for relaxed interaction in an environment that has pool tables, foosball, ping-pong, chess, dart throwing and poufs, and also a large terrace with green roof and spaces designed for rest. The cafeteria, equipped with special thermal-acoustic insulation provided by the green roof, has a diversified, balanced diet and environment to promote integration and strengthen the integration of employees at all hierarchical levels. For special moments such as celebrations, lectures, happy hour and other events of this type, Exatron has a truly different location. The Gourmet space, in addition to also using the natural climate provided by the green roof elements and herb bed, teas and spices, is equipped with a freezer, beer cooler, ovens, barbecue grills, stove, wood oven, armchairs and tables, and also has its ecological wood furniture and contemporary design, providing a coworking experience aligned with interaction and integration. The outdoor area has parking for 120 cars, shades, bicycle racks, gardens, fruit trees and doghouses.

A Exatron projeta e fabrica produtos de forma ecologicamente correta com vistas na preservação do meio ambiente, e que promovam economia de energia, aumento da vida útil das lâmpadas em comparação aos concorrentes, menor consumo próprio e funcionalidades adicionais.

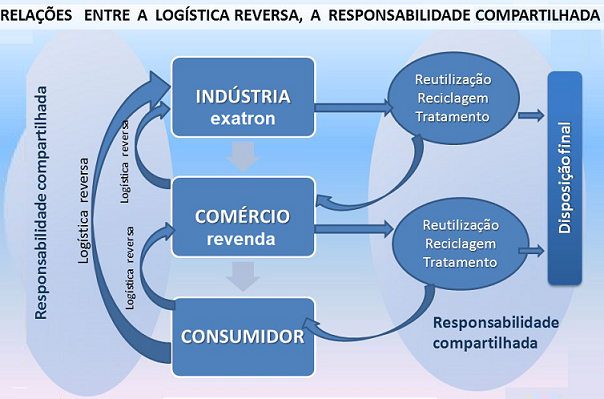

Exatron is committed to designing and manufacturing products in an ecologically correct way with a view to preserving the environment. The PNRS Law, 12,305/2010, more specifically in the third article, item XVII, defines that shared responsibility for the life cycle of products is a principle that divides the duties of mitigating the impact generated among all actors in the cycle, i.e. manufacturers, distributors, traders, importers, consumers and cleaning agents. The idea is that everyone who is part of a product's life cycle is responsible for actions that will reduce its impact. First of all, we are all consumers and therefore it is important to keep our individual actions aligned with environmental awareness. In view of this, Exatron agreed with its resellers to be part of the PELR – Exatron Reverse Logistics Program and receive the products by returning them to the manufacturer, and placed on the packaging the guidance for the consumer that the post-consumer product must be returned to resale so that disposal and correct destination are carried out through reverse logistics. The collected products return to Exatron, which sends them to recycling partners. In addition to PELR, the company is part of PRAC – Shared Environmental Responsibility Program (battery management plan – IBAMA – CONAMA Resolution 401/08), where it is responsible for recycling the total quantity of batteries sold, in addition to committing to environmentally appropriate disposal of products that undergo reverse logistics upon completing their useful life cycle.

We use cookies to ensure you get the best experience on our website. By continuing to browse, you agree to our privacy policy.